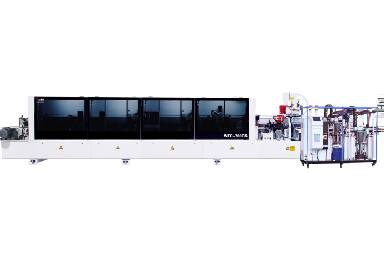

Nowadays, furniture factories basically have the figure of edge banding machine, edge banding machine can be highly efficient, high speed of the board for straight or slanting, edge banding, scraping, chamfering, trimming and polishing operations, etc.

But the furniture industrys carpenter furniture workshop itself has high dust and many wood chips. In addition,

https://www.falitmac.com/product_271.html with glue pot is considered a high temperature special machine, if used for a long time, there may be some machine problems

Knowing how to maintain the edge banding machine is particularly important, maintenance and protection of the edge banding machine will consume a certain amount of manpower and material resources, but the correct maintenance can extend the life of the edge banding machine, thereby improving efficiency.

Edge banding machine maintenance is very important, the following is to introduce the maintenance of Auto Edge Banding Machine, what to pay attention to when operating maintenance.

1. Sort out the debris and dust

Sorting out the production process of edge banding machine, wood chips and all kinds of plastic debris is inevitable, which will lead to the accumulation of wood chips and dust and thus lead to the formation of slating caused by machine jams, will also lead to flush saw blade scraper is not sharp and all kinds of cylinder is not sensitive, thus forming a normal use of the impact of edge banding machine. Therefore, it is necessary to tidy up some stains on the appearance of the machine in time and adhere to the neatness of the edgebanding machine, so that harmful acidic alkaline oily substances can be avoided to form corrosive damage to the appearance of the edgebanding machine body.

2. Regularly smooth the edge sealing machine

Every now and then, it should be smooth with smooth oil for each component shaft of the edge banding machine, remember not to play too much smooth oil, especially in winter, when the cylinder or exposed bearing smooth, do not use higher viscosity oil, otherwise it will be easier to stain ash, but also on the normal use of Auto Edge Banding Machine has an impact.

3.Regular inspection

Regular inspection of the edge banding machine for protection, in the process of protection to carefully check the edge banding machine gears, chain blocks, saw blades, bearings, scrapers, pressure wheel and other parts of the wear condition, to replace the damaged parts in a timely manner serious!

Check the rubber pot regularly for impurities, it is best not to mix a variety of brands of rubber, such as the need to change the rubber brand, please clean the rubber pot first, do not feel the same rubber color number to ignore the rubber brand.

Areas that need special attention when using Auto Edge Banding Machine

It is better to check the feed motor position reducer of the edge banding machine every half month to see if the oil volume in the reducer is suitable, and the guide rail of the edge banding machine should be tidied up every other week.

Workers should check the oil and water separator of the edge banding machine every day to see if there is a lack of oil and water storage. The oil and water separator is best to participate in the lower viscosity oil and gear oil, and if the conditions agree, please refill the special oil for pneumatic components to three-fifths of the oil cup.