Introduction

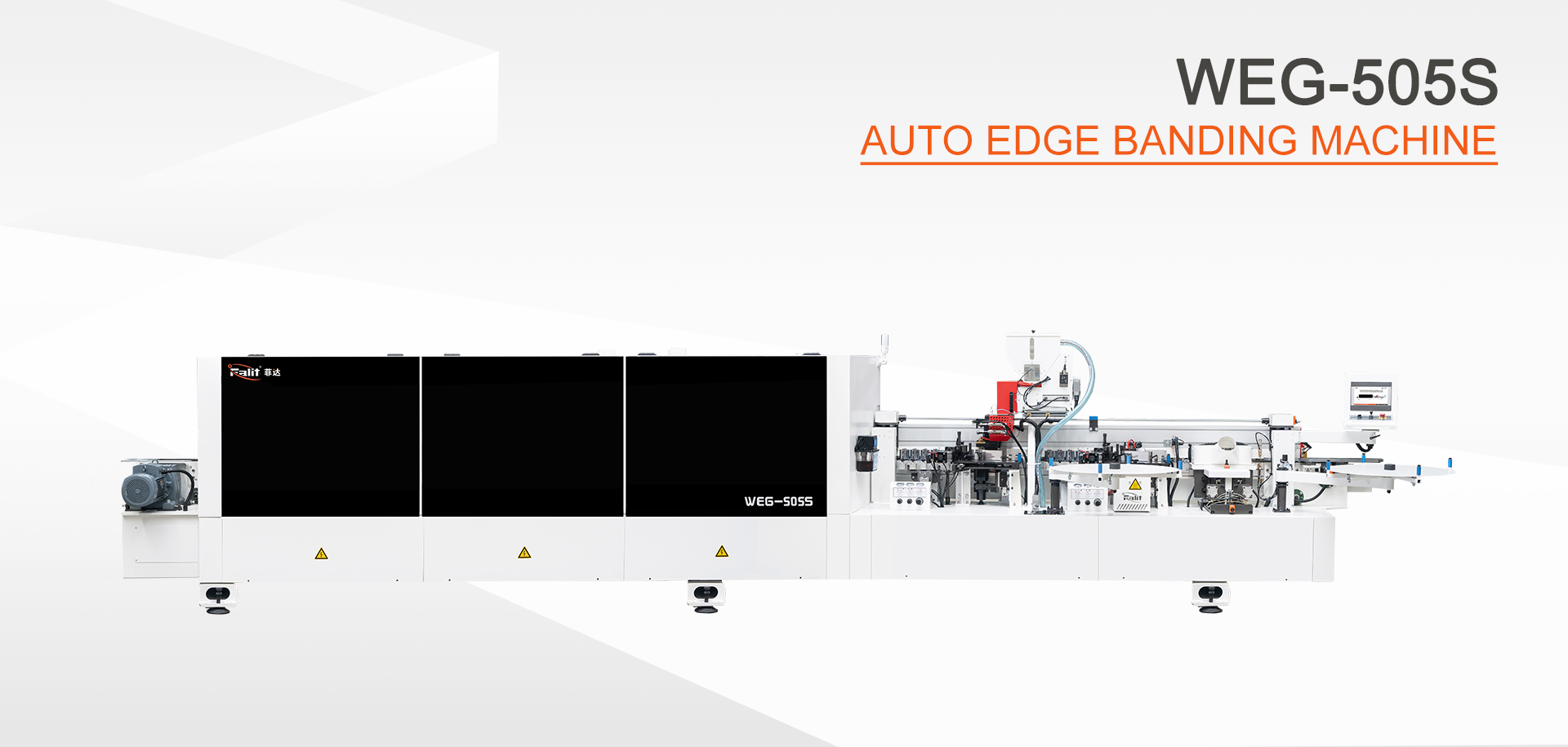

In the realm of woodworking and furniture manufacturing, the significance of an Auto Edge Banding Machine cannot be overstated. These machines streamline the process of applying edge banding to panels, enhancing both efficiency and aesthetics. However, choosing the suitable Auto Edge Banding Machine is critical to achieving optimal results and maximizing productivity. In this comprehensive guide, well delve into seven key factors that every prospective buyer should consider before making a purchase decision.

1.Quality and Durability

Durability and quality are paramount when investing in an auto-edge banding machine. Assessing the build quality ensures that the machine can withstand the rigors of continuous operation in a manufacturing environment. Look for machines constructed from robust materials and manufactured with precision engineering techniques. Additionally, consider reputable Auto Edge Banding Machine manufacturers known for producing high-quality, long-lasting equipment.

2.Machine Capacity and Specifications

Understanding the specific requirements of your woodworking projects is essential when selecting an Auto Edge Banding Machine. Evaluate the machines capacity and specifications to ensure it can meet your production needs. Factors to consider include feed speed, panel thickness capacity, and edge thickness capacity. By aligning the machines capabilities with your project requirements, you can ensure smooth and efficient operations.

3.Edge Banding Materials Compatibility

The versatility of an Auto Edge Banding Machine largely depends on its compatibility with various edge banding materials. Different projects may require other materials such as PVC, ABS, wood veneer, or melamine. Its crucial to choose a machine that can handle the specific materials youll be working with. Ensure that the machines specifications and features are suitable for the types of edge banding materials you plan to use, enhancing flexibility and efficiency in your operations.

4.Automation and Technology

The advancement of automation and technology has revolutionized the woodworking industry, and Auto Edge Banding Machines are no exception. When considering a purchase, explore machines equipped with advanced features such as automatic trimming, glue application systems, and intuitive control interfaces. These technologies not only improve efficiency but also enhance the precision and quality of edge banding applications. Investing in a machine with cutting-edge technology can significantly boost productivity and streamline your workflow.

5.Maintenance and Support

Regular maintenance is essential to keep your Auto Edge Banding Machine operating smoothly and efficiently. Before making a purchase, inquire about the manufacturers maintenance recommendations and schedules. Additionally, consider the availability of technical support, spare parts, and warranty coverage. Choosing a reputable Auto Edge Banding Machine supplier that offers comprehensive support ensures that any issues can be promptly addressed, minimizing downtime and maximizing productivity.

6.Cost and Return on Investment (ROI)

While upfront costs are an important consideration, its essential to evaluate the long-term benefits and return on investment (ROI) of an Auto Edge Banding Machine. Look beyond the initial price tag and consider factors such as maintenance expenses, energy consumption, and productivity gains. Calculate the total cost of ownership over the expected lifespan of the machine to determine its actual value. Investing in a high-quality machine may require a more considerable upfront investment but can yield significant cost savings and efficiency improvements over time.

Conclusion

In conclusion, purchasing an Auto Edge Banding Machine is a significant investment for any woodworking or furniture manufacturing operation. By considering the seven critical factors outlined in this guide—quality and durability, machine capacity and specifications, edge banding materials compatibility, automation and technology, maintenance and support, and cost and ROI—you can make an informed decision that aligns with your production needs and budget constraints. Remember to choose a reputable Auto Edge Banding Machine manufacturer or supplier and prioritize long-term value over short-term cost savings. With the suitable machine, you can enhance efficiency, precision, and quality in your edge banding operations, ultimately driving success and profitability in your business.