Users who are familiar with edge banding machines know that edge banding machines are divided into automatic and semi-automatic. But some customers need to learn how to choose when buying an edge banding machine. They have their characteristics, depending on which is more suitable for their production needs. To help you choose the most suitable edge banding machine, we will introduce the main features of semi-automatic edge banding machines and automatic edge banding machines for you to identify.

Functional differences

1: Semi-automatic edge banding machine has the functions of preheating, gluing, trimming, scraping, and polishing. Some manufacturers even omit the function of preheating edge material to save production costs.

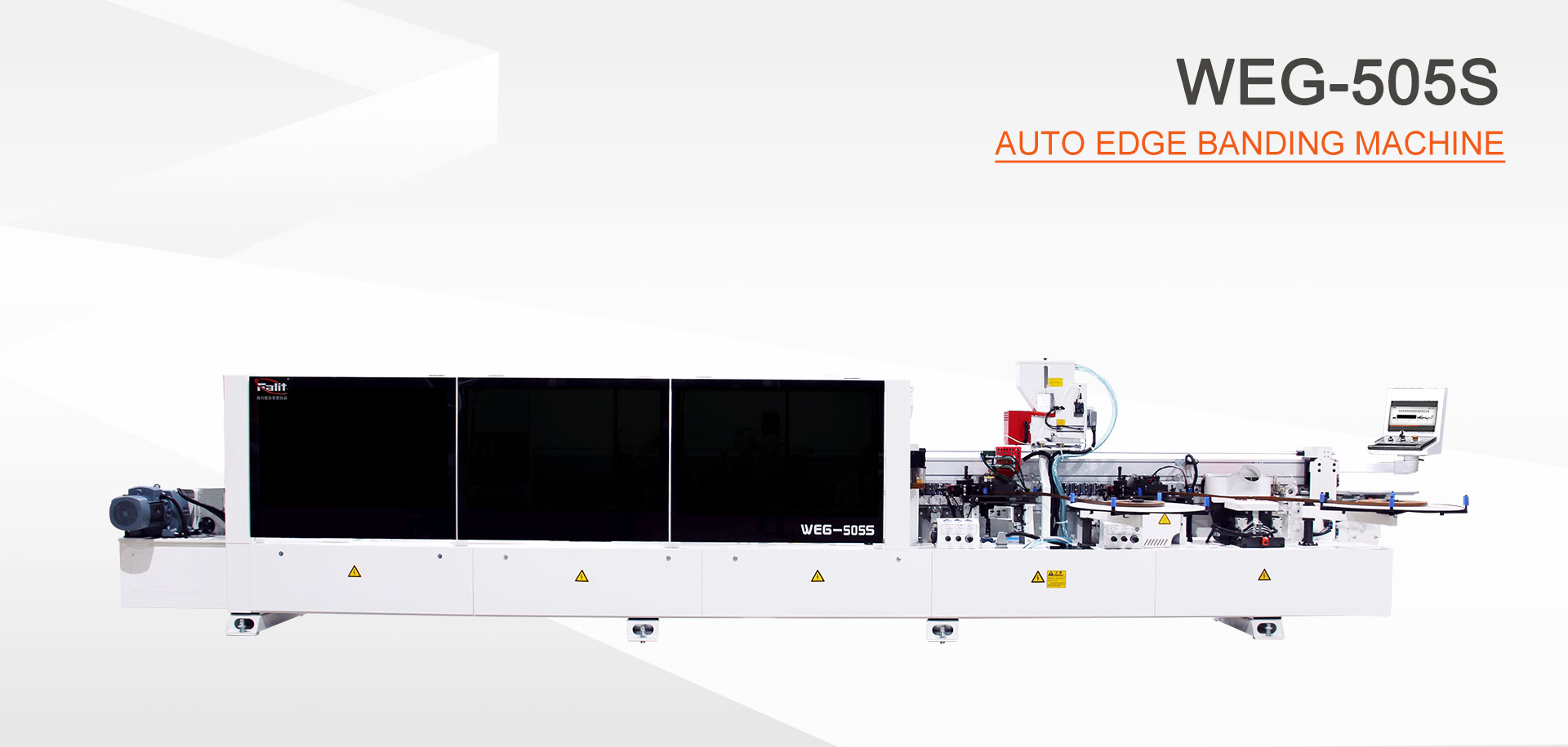

2: Automatic edging machine has more complete functions, mainly pre-grinding, gluing, banding, binding, rough trimming, finishing, scoring, polishing, slotting, etc. The main feature is that the degree of automation is higher than that of semi-automation, edging efficiency is also higher, and the beauty is also higher.

Practical differences

1: The semi-automatic edge banding machine mainly applies to the edge banding of MDF and joinery and the automatic production line for conveying the edge banding board.

2: Automatic edge banding machine mainly applies to the edge banding of medium solid wood panels, planer beds, polymer door panels, and plywood. It is suitable for large and medium-sized furniture, cabinet, and other panel furniture edge banding machine manufacturers.

In addition to the difference in appearance, the most fundamental difference between the two machines is the function. Compared with the semi-automatic edge banding machine, the automatic edge banding machine is relatively complete. Therefore, you can use a semi-automatic edge banding machine if the factory is small or the banding board is only MDF and detail board. If it is some high-grade custom furniture edging, it is recommended to use the fully automatic edging machine. Therefore, edge banding machines should consider their production edge banding needs in addition to quality and price when buying and selling.

Buy an edge banding machine. In addition to knowing the difference between an automatic edge banding machine and a semi-automatic edge banding machine, but also need to understand in detail the specific functions of the edge banding machine so that the purchase of an edge banding machine can know whether the equipment meets their processing needs, in addition to the following will introduce the purchase of edge banding machine, how to maintain the equipment to extend the service life.

What are the functions of a woodworking edge banding machine?

Edge banding machines can be accurate and efficient for linear edge banding, trimming, and polishing of furniture panels, but many people are in the process of using edge banding machines but need to pay attention to the maintenance of the edge banding machine. Although the maintenance of an edge banding machine may cost a certain amount of human and material resources, it can extend the edge banding machines service life and improve work efficiency. The following is an introduction to the maintenance of the edge banding machine and the four aspects of the edge banding machine attention.

Functions include.

1. Edge cutting: Through the precision linear guide movement, the automatic model tracking, and high-frequency, high-speed motor fast edge cutting structure to ensure a smooth and flat edge cutting.

2. Gluing: Through the particular structure, the panel and the edge tape are evenly coated on both sides to ensure a more firm edge banding.

3. Pre-milling: Using double milling knives to trim the wave marks, burrs, or non-vertical phenomena caused by the cutting board saw and the cutting board saw to achieve a better edge banding effect. Make the edging strip and the board fit more closely, with better integrity and more beautiful.

4. Rough/fine trimming: Adopt automatic tracking and high-frequency, high-speed motor structure to ensure the flatness of the upper and lower parts of the trimming board. It is used to repair and process the excess edge tape on the top and bottom of the board .

5. Corner trimming: top and bottom rounding device to make the corner of the board more smooth and beautiful.

6. Edge scraping: It is used to eliminate the ripple marks produced during the cutting process of non-linear movement of trimming so that the upper and lower parts of the board are more flat and smooth.

7. buffing: Use a cotton buffing wheel to clean the processed board and make the edge banding surface smoother by buffing.

8. Grooving: used for the closet side panel and bottom panel direct grooving, reducing the cutting saw process, more convenient and fast; also can be used for door aluminum edge grooving.

If the equipments life is long, we need to maintain it. Then the edge banding machine should be how to maintain it?

How should the edge banding machine be maintained?

1. Keep all parts of the body clean. For example, the glue brought by the board near the glue pot will dry on other parts and directly affect its everyday work.

2. In the pre-milling, cutting edge, and cutting edge scraping parts, there will be a lot of edge banding chips. Even if there is a vacuum device, it will need to be cleaner. The flying edge banding chips will affect the sliding and rolling parts and the cutting edge. So we have to clean up the banding edge with edges every time.

3. Inspection of running parts, regularly check the sound and temperature of each running part for any strange sound and heat.

Regularly refuel the running parts.

Choose a reliable edge banding machine manufacturer.

Nanxing Group is a furniture woodworking machinery manufacturer with 26 years of manufacturing experience. We have a professional production factory and R & D team only to manufacture high-quality furniture woodworking machinery. Welcome to consult, and we will provide you with complete edge banding machine products and solutions.