In the world of manufacturing, efficiency is critical to success. Any process that can be automated or simplified can save costs and increase production. One of the most innovative machines in the industry today is the CNC door four edges saw. In this article we will discuss in depth the advantages of using a CNC door quad saw, the importance of choosing a reliable CNC door four edges saw manufacturer, and how this technology can maximize efficiency in the manufacturing process.

Advantages of Using a CNC Door Four Edges Saw

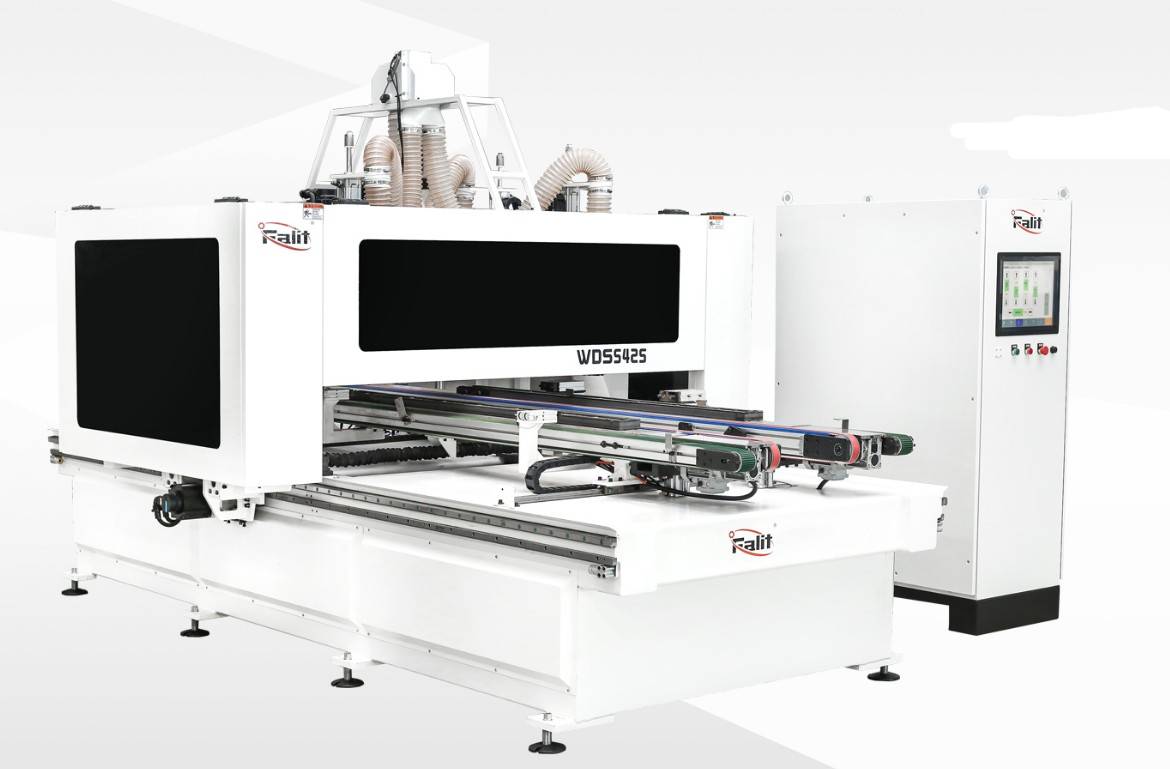

A CNC door four edges saw is a computer-controlled machine that can precisely cut and shape door panels to specifications. There are numerous advantages to using this machine in the manufacturing process, including the following:

1. Increased Efficiency: A CNC door four edges saw can complete multiple cuts in a fraction of the time it would take a human operator to do the same job. With the ability to automate the cutting process, manufacturers can increase production rates and reduce labor costs.

2. Consistent and Accurate Cuts: The CNC technology in the machine ensures that the cuts are precise and consistent, resulting in high-quality door panels every time. This reduces the risk of errors and the need for rework, saving time and money in the long run.

3. Versatility: A CNC door four edges saw can cut through various materials such as wood, aluminum, and PVC. This versatility thus makes it an excellent investment for manufacturers of different materials.

Importance of Choosing a Reliable CNC Door Four Edges Saw Manufacturer

Choosing a reliable CNC door, a four-edge saw manufacturer, is crucial to maximizing efficiency and ensuring the machines durability. A reputable manufacturer will provide high-quality machines built to last and offer excellent customer support and technical assistance. Here is a list of some factors to consider when choosing a manufacturer:

1. Reputation: Look for a manufacturer with a proven track record of producing high-quality machines that meet industry standards. You can check online reviews and ratings of products to see what other customers have said about them and the manufacturer.

2. Features and Capabilities: Choose a manufacturer that offers machines with the latest technology and features, such as automatic loading and unloading, dust collection systems, and user-friendly controls. These features can help further increase efficiency and reduce labor costs.

3. Technical Support: A manufacturer that provides excellent customer support and technical assistance will ensure that any issues with the machine are resolved quickly and efficiently.

Maximizing Efficiency with CNC Door Four Edges Saw in the Manufacturing Process

A CNC door four edges saw can maximize efficiency in the manufacturing process by reducing labor costs and increasing production rates. With the ability to automate the cutting process, manufacturers can significantly improve their output and reduce the need for human intervention. This technology ensures consistent and accurate cuts, always resulting in high-quality door panels.

Conclusion

Conclusion

A CNC door four edges saw is an excellent investment for manufacturers looking to maximize efficiency in their manufacturing process. By choosing a reliable CNC door four edges saw manufacturer and taking advantage of the benefits of this technology, manufacturers can reduce labor costs and increase production rates while maintaining high-quality standards.